2880: Sheet Bend

| Sheet Bend |

Title text: A left-handed sheet bend creates a much weaker connection, especially under moderate loads. |

Explanation[edit]

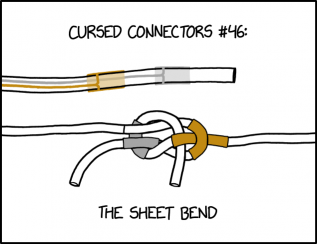

This is the seventh installment in the series of Cursed Connectors and presents Cursed Connectors #46: The Sheet Bend. It follows 2642: Meta-Alternating Current (#120) after about 1.5 years. This is the longest break between two connectors, and so far it is also the last to be released. At the time of release this was also the lowest number used for a cursed connector, replacing 2495: Universal Seat Belt (#65) (with 2507: USV-C (#280) being the one with the highest number).

This comic shows two double-core cables being joined in a knot to make an electrical connection. The knot used to tie the two halves of the cable is a sheet bend, which is often used to join two ropes of different thicknesses, and explains the name for this type of cursed connector, which seems to be made by ensuring each cable end is terminated with identical electrical connections to the outer sleeving in a manner similar to various 'ring' connections in 'phone' connectors, but as significantly longer and more separated sleeves.

In contrast to more normal methods, Randall has proposed yet another of his 'cursed' connectors. This one requires no additional plugs, sockets, enclosures or even tools to use. Any two cables with such ends can be brought together and simply knotted together. This particular knot, and the specific spacing of its two external conductors, appears to be chosen in order to rather elegantly create consistent connections between the respective contacts, with a minimum of fuss.

However, there are potentially many unaddressed but conspicuous problems with this connection method, thus rendering it a 'cursed' connector. Among the issues are:

- The need to have suitable ends to any cables, which would involve issues in the manufacture (and the materials used) as cable's cores must be separately tapped and reliably connected to an external length of conductive sleeving.

- The consistent ability of a cabler to tie the correct knot, which is a skill that will need practice. Done wrongly the electrical connections may not be made correctly, or at all (including as discussed in the title text).

- Even if initially tied correctly, knots can slip or distort when subsequently pulled more taut.

- Even if the user is a competent and consistent knot-tier, this is inherently more effort, and therefore less convenient, than the more usual practice of simply pushing two connectors together.

- The external conducting patches of the cable are an uncommon feature of electrical junctions, with issues in both high-power and low-power situations.

- If the cables are supposed to carry high voltages, any bare conductors ought to be safely isolated from easy contact with equipment/people. In particular, plugs and sockets that carry anything approaching mains-voltages have active and passive elements integrated which protect the person connecting or disconnecting the equipment. There is no physical precaution visible to protect the person tying or untying the cable from potential shock. Instead, they must rely upon the other end of the potentially 'live' cable being disconnected. And, when left unattended, there would continue to be a high risk of injury (including death), fire or more basic damage due to the lack of any proper physical isolation.

- Low-voltage cables that pass signals between equipment (e.g. networking data or audio signals) are susceptible to external contact disrupting the flow. Random static charges, built up and transfered into the connector, instead make other equipment or people the potential threat to the cabled-up equipment, causing disruption to the normal purpose of the cable, where a more standard plug-and-socket/hard-wired connection would not.

- The bending, twisting and rubbing of the cables each time the cables are connected and disconnected will very likely cause wear and damage over time.

- The knot provides a possible snag point by which the cable could be caught; anything which catches or tugs on the knot could cause disconnection.

The title text says that a left-handed sheet bend would provide a weaker connection. The difference between a left-handed and right-handed sheet knot is that the two free ends of the knotted 'cords' are in the same orientation for a right-handed sheet knot (here, both on the lower side of the image), but on opposite sides for a left-handed sheet knot. A left-handed sheet bend provides less strength to the knot, due to the possibility of distorting (e.g. capsizing) and/or allowing one or both cables to pull through the knot.

This makes the title text a pun on the double meaning of "moderate load", which could be a moderate amount of physical tension applied through the cables or a moderate amount of electrical current passing through them. Together, it would be expected that tension drawing two conductive surfaces together would create less resistance between them, strengthening the electrical connection as well, but only if the knot holds as expected.

A knot was also the subject of the relatively recent 2738: Omniknot.

Transcript[edit]

- [Above the drawing there is a header. Below the header there is a double-core wire going in from the left and stopping just past the middle of the picture. It shows how the inside of the wire looks and how the silver and golden wires inside are connected to two rectangular pieces of silver and golden material respectively. The golden piece is to the left and the silver piece to the right, closest to the end of the wire. Beneath this wire is shown two double-core wires forming a knot of the sheet bend type. Here it becomes clear that the silver and golden pieces are on the outside of the wires (but connected to the wires running inside the wires). In the knotted part of the wires gold touches gold and silver touches silver, without them touching the other color. Beneath this knot there is a label for the connector.]

- Cursed Connectors #46:

- The Sheet Bend

Discussion

Why is this called a "sheet" bend? SystemParadox (talk) 21:17, 12 January 2024 (UTC)

- I don't know the full answer but it's a sailing thing: the 'sheet' is the rope you pull in or let out to control the position of the sail. I guess bend describes the category of knot. 172.70.90.48 21:23, 12 January 2024 (UTC)

- NO NO NO. The sheet is the sail. JohnB (talk) 21:36, 12 January 2024 (UTC)

- never has a sail been called a sheet by a sailor. It is a rope, attached to a sail. It has a very precise and specific meaning. 172.69.58.200 (talk) 16:18, 18 February 2024 (please sign your comments with ~~~~)

- It is the rope - Sheet (sailing). "In sailing, a sheet is a line (rope, cable or chain) used to control the movable corner(s) (clews) of a sail." 172.71.242.5 21:56, 12 January 2024 (UTC)

- Huh. Dueling Wikipedia articles. The Sheet_bend article has a definition section that says the term "sheet bend" derives from its use bending ropes to sails (sheets). But the Sheet_(sailing) article says a sheet is a line used to control the movable corner(s) of a sail. JohnB (talk) 23:08, 12 January 2024 (UTC)

- A sail is never, and was never, properly called a "sheet", since at least the 13th century. The Wikipedia explanation of the name is misleading. According to https://www.etymonline.com/word/sheet, it's "shortened from Old English sceatline "sheet-line," from sceata "lower part of sail," originally "piece of cloth," from same Proto-Germanic source as sheet (n.1)." Jlearman (talk) 17:44, 13 January 2024 (UTC)

- When I took a sailing class as a kid they used the word “sheet”, I think it was the lines connected to the sails used for adjusting them? 108.162.245.82 19:46, 13 January 2024 (UTC)

- A sail is never, and was never, properly called a "sheet", since at least the 13th century. The Wikipedia explanation of the name is misleading. According to https://www.etymonline.com/word/sheet, it's "shortened from Old English sceatline "sheet-line," from sceata "lower part of sail," originally "piece of cloth," from same Proto-Germanic source as sheet (n.1)." Jlearman (talk) 17:44, 13 January 2024 (UTC)

- Huh. Dueling Wikipedia articles. The Sheet_bend article has a definition section that says the term "sheet bend" derives from its use bending ropes to sails (sheets). But the Sheet_(sailing) article says a sheet is a line used to control the movable corner(s) of a sail. JohnB (talk) 23:08, 12 January 2024 (UTC)

- NO NO NO. The sheet is the sail. JohnB (talk) 21:36, 12 January 2024 (UTC)

- Sheet is used to adjust/trim a sail and a halyard is used to raise/lower sails. Sheet only refers to a rope, not the sail. Standing rigging are the ropes which supports masts including shrouds and stays. Running rigging adjusts the position of sails and spars including halyards, braces, sheets and vangs. Sheets are used to control clews (movable corners of sails). 172.69.58.200 (talk) 16:11, 18 February 2024 (please sign your comments with ~~~~)

- A sheet bend joins two ropes. Not fabric to rope. The following comment, for example, is incorrect. 172.69.58.201 (talk) 16:13, 18 February 2024 (please sign your comments with ~~~~)

- The sheet bend is named for its ability to to secure a sail, or sheet. You fold over the corner of the sail and that's one of your "ropes". The sheet bend is generally used as a knot for tying a large, inflexible rope (or rope-like object) to a smaller, more flexible rope.172.69.70.22 22:30, 12 January 2024 (UTC)

- I would take the Ashley Book of Knots as authoritative. Sheet Bend is the first knot in the book, and is always (in modern terms) rope-to-rope, not to sail. It is one of the basic knots. https://en.wikipedia.org/wiki/The_Ashley_Book_of_Knots https://en.wikipedia.org/wiki/Sheet_bend

- -- PRR (talk) 04:04, 13 January 2024 (please sign your comments with ~~~~)

- But what dispute are you taking TABoK's authority on? Two things can have the same name in different contexts (or namespaces). And does Ashley use anything other than ropes exclusively in the whole book? 108.162.241.170 14:42, 14 January 2024 (UTC)

- I added a link to the wikipedia entry, it explains the name. Barmar (talk) 21:25, 12 January 2024 (UTC)

- Because it's a sheet way to connect cables?172.70.90.137 09:58, 15 January 2024 (UTC)

Presumably the "different loads" title text is a pun between electrical load and mechanical stress on the knot? Jim-at-home (talk) 21:56, 12 January 2024 (UTC)

“silver being joined to silver and gold being joined to gold within the insulating white cable” is not the conventional way to join cables. Unless you are joining one cable to itself (like a Möbius strip), you have two cables with insulation. And usually you use non-cursed connectors, where you first remove the insulation at the end of the cable and then crimp or solder the conductors to metal parts of the connector; or solder the conductors and then add a different type of insulation for protection; or use screw terminals;... Only with insulation displacement connectors you keep using all the insulation of the two cables. And finally, conductors are usually copper or aluminum, and very rarely silver and gold. --162.158.94.141 08:45, 13 January 2024 (UTC)

- I think the gold and silver is just color coded for the reader. Not that they are meant to indicate that the conductors are made from this material. Apart from that you comment sounds like you know what you are talking about. So please improve the explanation if you can. --Kynde (talk) 10:58, 13 January 2024 (UTC)

- I changed it to gold- and silver-colored. It was obvious to me that it was the colours used in the comic that were being referenced, but fixed for the avoidance of doubt. The join being made within the one cable was clearly an error though. 172.70.85.161 22:13, 13 January 2024 (UTC)

- cables often have the signal parts copper-colored (described gold atm) and they are obviously copper, and the outer ground more the color of steel or something, not sure what metal it is, but it’s easy to solder like copper or silver is, not aluminum which is very hard to solder. usually gold and silver are used at the contacts of a connector, not inside a wire, i don’t know who would ever make that mistake. 108.162.245.83 19:49, 13 January 2024 (UTC)

- "more the color of steel or something, not sure what metal it is, but it’s easy to solder like copper or silver" Traditionally tinned copper. Tinned not just for identification, or easier soldering, but because early rubber insulation actively rotted copper and tinning slowed the damage. Many sorts of damage, why much copper today is silvery. PRR (talk) 04:16, 14 January 2024 (UTC)

- Not wishing to spoil it, but the series finale of a certain radio comedy reveals... ah well, that's the spoiler (in the article, if you read that far down... rather than just listen to it if you haven't heard about it already but now think you like the premise). 172.69.79.188 21:01, 13 January 2024 (UTC)

- cables often have the signal parts copper-colored (described gold atm) and they are obviously copper, and the outer ground more the color of steel or something, not sure what metal it is, but it’s easy to solder like copper or silver is, not aluminum which is very hard to solder. usually gold and silver are used at the contacts of a connector, not inside a wire, i don’t know who would ever make that mistake. 108.162.245.83 19:49, 13 January 2024 (UTC)

Okay I looked at the wikipedia article and the knot depicted in the comic looks like a right handed one. I still don't know why it's called right handed, or why the left handed one is insecure.198.41.236.207 11:46, 13 January 2024 (UTC)

- It's not. Ropes and heavier ropes (called cables) are commonly made by twisting smaller ropes together, the twist direction (terminologically the 'lay' of the rope, (s-laid or z-laid)) is the main thing (that I know about) that can make chirality (handedness) of knots important to their strength. Electrical cables and wires aren't usually expected to have any tensile strength, and their tensile components aren't usually twisted in a way that would affect their strength. (Sorry for all the parentheticals.) 108.162.241.130 14:56, 14 January 2024 (UTC)

- As I understand it (at least in knots that I'm familiar with), it's not chirality (like stereo isomers) but cis-/trans-ness (e.g. isomers which have active groups pointing in different directions across a double-bond).

- If the left cable came into the right's loops on on the bottom, dove under the two loops of the RH cable, over the conductor then under then over to have the loose end emerge where the offscreen-length currently comes in, then it'd be electrically the same but any tension would pull more off-axis and the knot could 'capsize' into an unwanted form (topologically similar, but with different relative loops.

- If you did that but also rethreaded the RH length to come up through the LH's loop (as now), but then passed over the top, down behind the two LH bits (free and loose end) to go back over the (lower) LH, under itself then over the (upper) LH, to dangle free, it would be a chiral inversion and (as you say) probably not greatly affected by the cable's own rotational symmetry.

- Re-rethread the LH loop as it was, and you'd get a chiral alternative to the first 'capsizable' change.

- Proper mathematically-inclined knot-theorists probably have better terms to use for both chiral and cis-trans transforms (as well as functional sub-mirroring such as the difference between reef and granny). There will already be terms known amongst practical knot-practioners such as sailors and other riggers, but (at least until "knot bibles" were written) they'll have been given homegrown/traditional terms that might not be particularly consistent with other knot-cultures. 172.69.43.163 17:26, 14 January 2024 (UTC)

- ^^^^ Addendum... Maybe this link I just found is relevent, from a quick scan of it... Or maybe not. ~same IP/time as above .sig~

A note I nearly added in the bit about short-circuits (or, as I added, 'un'circuiting) is that the electrical behaviour of the knot is different according to which 'end' slips. If the left-side cable 'slips through' enough, then its gold and silver bits of sheath could contact (would short-circuit any current driven at that side). If the right-side cable slips out, it is in no danger of doing so for a right-driven current (it would just disconnect). That ignores the cross-talking that could occur (on one conducting line at a time, so may not matter if there's no external ground-return element, except as far as not being a proper connection any more), or both ends slipping (where one of the LHS sheaths might shuffle into a position to bridge the two RHS sheaths). But, as tied, the LHS silver (being bent in and out of the page around its crossing counterpart wire) seems unlikely to be pressed against both gold and silver, should it trivially untwine/slip through. Actual studies with actual knots might be useful. I thought I had a spare length of unterminated Cat5, nearby, but apparently (k)not... that, with some coloured permanent marker-pen marks made upon it, would probably have made a decent analogue for visual analysis of failure conditions. Maybe I'll de-plug an old cable (I've got a number of damaged USB cables I could chop, but their being thinner would change the scale and dynamics of the knot, meaning I might as well just use a scrap of twisted-pair internally-sheathed strands). – But I thought you'd like my mind's-eye analysis of the knot behaviour, before I get around to trying anything practical to this end. 141.101.99.7 17:08, 13 January 2024 (UTC) (<- ex Cub-/Boy-/Venture-Scout, but never got any Knot Untying badge... that brief stint with escapology aside... ;) )

This comic contained material familiar to a hobby engineer that was cast critically and derogatorily (e.g. “sheety” bend) throughout the explanation. I edited a lot of it. I’ve seen this happen repeatedly in other explanations. I don’t edit most of them. 172.71.150.155 18:41, 13 January 2024 (UTC)

"this is a scenario commonly encountered by hobby engineers from the last millenium" "commonly"? Can any hobbyist engineers from the last millennium attest? Also, this sounds ageist - is it ageist? 172.70.86.166 21:56, 13 January 2024 (UTC)

- Well, I definitely did electrics/electronics pre-millenium. I'm not at all unhappy with the idea with the possibility of an occasional 'bodge job' connection having happened (e.g. tying a cable in a simple knot, in suitable cases, to add mechanical resistance to any further tendency for a cable to be tugged out of a grommit-hole and the core conducting wires being tugged out of whatever terminal/patch-block they need to be connected to - or, more likely, pulling the core copper strands beyond their tensile limits).

- Although (while I respected the idea of this being based upon a repair-bodge), I don't see this as a "this wire was damaged, this is how the two ends are reconnected", but rather as a deliberate cable termination method (like adding moulded plugs/etc) which could then be mated end-to-end with another similarly terminated cable. (Like using a gender-changer 'double-socket' between two phono-ended lengths of cable, or using a BNC T-connector just to join two lengths of networking cable but without the need for the extra connector and adding intrinsic tensile resistance - though actually not as much as the BNC 'bayonet' version already does...)

- If I was writing this from scratch, I'd actually remove all the 'repair' aspect of it, TBH. It looks more like a deliberate patch-type cable (1x2core) manufactured to be directly and hermaphroditically compatible with any other such cable, tied together without the need for tools (screwdrivers, crimpers, punch-downs, etc) and untied as and when required (at least as easily as any similar rope-knot can be undone, which isn't always a given if mishandled and overtightened).

- I'd also be looking at various knots and working out which (if any) could support more than two contact-patches/sleavings per cable, for three-core or more-core connections between any two such cables. The geometry of the knots would define roughly where (and how long) the external contact-sleaves would need to be (presumably identical for both cables) such that they made appropriate connections between the two halves (cross-overs could be allowed, but that'd have to be down to the IEEE specifications of how to detect/interpret RX/TX assymetry at the end devices, etc). But then I'd also be writing a vastly more complicated alternate explanation. Perhaps just remove the bodge-job implications, someone? Clearly it's not an end-user bodge. Though it could be a manufacturer/industry bodge (such as using an 8P8C connector for essentially 6P4C purposes). 172.69.79.138 00:53, 14 January 2024 (UTC)

I use the reader app in inverted color mode, so I could not for the life of me figure out what all the discussion about silver and gold was about. Also, can I just comment on how the conductive sleeves are magically flexible? I wonder if they are braided. Even then, this would severely limit how tight the knot could be pulled. 162.158.154.238 13:26, 14 January 2024 (UTC)

- I initially imagined either a particularly ductile 'foil' or, as you say, braided (like an STP cable's 'S' layer), though the failure modes of both (tearing or fraying) are potentially problematic. Perhaps a conductive polymer of similar mechanical flexibility to the non-conductive regular sheath. The attachment of respetive core to the outer seems to me the most intensive process.

- I once jury-rigged two cameras on a length of CAT5, using two pairs each for power/signal. One camera was around half way along the cable from where it was commonly terminated, but rather than than cutting the cable entirely and reconnecting the 'onwards' TPs (or threading a half-used full cable and a half-used part-length through the false ceilings/etc) I made a careful slit in the outer insulation (and shielding foil/braid, whatever it had), pulled the two chosen pairs out enough to get the necessary length of mid-cable free ends for my purposes and then snipped just those.

- It wouldn't need as much work to connect outer-conducting sheathing to an inner core. Possibly an into-insulation 'displacement' blade, but not sure how you'd guarantee the (single, and only) inner core contact, so slitting outer insulation, fishing for the chosen inner-core, piercing, twining and/or wrapping that conductive strand then reinsulating as necessary or shrink-wrapping with the 'conductive rubber' outer (preventing the slit from tearing too far open on bending). Twice, though you don't need to preserve the 'gold inner' up to or beyond the 'silver inner' tapping point.

- I would imagine (if this were a serious cable-end spec) there'd be careful balancing of robustness and flexibility of the materials and construction methods in use. But handwaved away, in our 'reality'.... 172.69.43.163 17:26, 14 January 2024 (UTC)

- ...see Conductive elastomer (and some of that article's onward links) for a possible type of material to use. 141.101.98.156 18:32, 14 January 2024 (UTC)

Y'know, I've read every XKCD comic. For some reason, this one makes me the most uncomfortable. I hate it. No idea why. Magicalus (talk) 04:46, 16 January 2024 (UTC)

- Knot category?

We've seen some recurring knot-themes, I was thinking. A quick check shows that it's not as overwhelming as I thought it was, but here's what I easily found anyway (possibly missed some, as I skimmed things).

- 595: Android Girlfriend - averted, but knots are mentioned/could have been expected in the parodied scenario (probably not really so cattable).

- 730: Circuit Diagram - drawn knot

- 1572: xkcd Survey - mentioned as an option

- 1762: Moving Boxes - written down (ambiguously)

- 2738: Omniknot - full-fledged 'knotty comic'

- ...this one, as above.

So it might just be the two 'proper knot-focused' comics, but (like 'birds' or 'real people' as categories) two or three others that should be considered relevant. Maybe wait until there's a third (it might take a year?), but placing the groundwork for it. Or maybe even being sufficient to prompt someone to act sooner, now that we can be sure that Knots is one of the many subjects Randall may dive into. 141.101.99.131 18:52, 14 January 2024 (UTC)

- The android comic doesn't mention knots. It is only the explanation here that does. The circuit diagram may have a knot, but it is not labeled, and could be something else. Not like saying this is a comic about knots. Of course it has a relation to this comic, but the relation is more in the connector than in knots. The survey doesn't have knot mentioned in the actual comic. Knots are for sure mentioned in a word in Moving boxes, but the comic is not about knots. Which leaves only Omniknot and this one, and I think even three about knots would be too little for a category. So unless there are at least a couple more, it is way too soon to make a knot comic category. But would be fine to include a link between the two knot comics. I will do that! --Kynde (talk) 07:43, 15 January 2024 (UTC)

- (You'll note that I expicitly pre-stated each of your 'objections', already. Not sure, then, why you thought I didn't realise any of it...) As I said, I had an impression that it was a well-used trope, here, but found it less so when I checked. But definitely not an unused one. So marked it here to avoid having to necessarily recheck everything once the next one arrived (or the one after that, etc, if still not conclusive). Although it's also possible I missed other good exameples, already... ;) 172.69.195.229 17:21, 15 January 2024 (UTC)

Add comment

Add comment

- (You'll note that I expicitly pre-stated each of your 'objections', already. Not sure, then, why you thought I didn't realise any of it...) As I said, I had an impression that it was a well-used trope, here, but found it less so when I checked. But definitely not an unused one. So marked it here to avoid having to necessarily recheck everything once the next one arrived (or the one after that, etc, if still not conclusive). Although it's also possible I missed other good exameples, already... ;) 172.69.195.229 17:21, 15 January 2024 (UTC)